Difference between revisions of "Ridenour Mysteries Of Particle"

Mathistruth (talk | contribs) m (Protected "Ridenour Mysteries Of Particle" ([edit=sysop] (indefinite) [move=sysop] (indefinite))) |

m |

||

| Line 44: | Line 44: | ||

==Reference== | ==Reference== | ||

The article is courtesy of USBC | The article is courtesy of USBC | ||

| + | [[Category: Cover Technology]] | ||

Latest revision as of 10:42, 22 April 2011

Unlocking the Mysteries of Particle-Ball Performance

In March 2008, the United States Bowling Congress adopted a new equipment specification that placed a limit on the Surface Roughness Ra value of bowling balls manufactured after April 2009. Since its adoption, that specification has been one of the most heavily-researched topics among bowling ball manufacturers, bowlers and USBC personnel. This fact demonstrates the high level of interest the bowling world has in issues relating to bowling ball motion. For that reason, the USBC Equipment Specifications and Certification department sought to clear up the confusion surrounding another popular topic relating to bowling ball motion: the use of particles or fillers in bowling ball coverstocks.

What is a particle or filler? When ball manufacturers talk about these particulates, they are discussing anything that is added to the A, B, and plasticizer parts of a bowling ball coverstock. These filler materials can increase or decrease the overall performance of a bowling ball depending on what type they are, the quantity in which they are used and the base resin formula of the coverstock.

One of the most commonly-used fillers in bowling ball coverstocks is the pearlized compound that makes one's resin a pearl resin instead of a solid resin. Pearlized bowling balls are, in actuality, particle bowling balls since they employ the addition of a filler material to the base coverstock resin. Most bowling ball manufacturers use mica flake particles in order to achieve this distinction in pearlized balls, which have been part of the bowling landscape for decades.

However, over the last decade, in response to new, slicker lane conditioners and the constant demand for increased ball motion, manufacturers began adding particles and fillers to solid resin coverstocks. When this practice began, companies infused bowling balls with particle loads as high as seven to ten percent, which resulted in coverstocks containing particles that were nearly large enough to be seen with the naked eye. Bowling balls such as Storm's La Nina and the Ebonite Tombstone exemplified this practice.

Over time, manufacturers began scaling back on the amount of particle used in each ball. In the current marketplace, a highly-loaded particle ball will contain a load of just three to five percent. The shrinkage in particle load levels was brought about by the difficulty of producing higher-loaded particle balls and the adverse performance traits demonstrated by some of the more highly-loaded balls.

The adverse performance traits exhibited by some highly-loaded particle balls was widely documented and discussed in industry circles and bowling forums alike. The negative publicity surrounding some of these balls led many bowlers to shy away from particle bowling balls altogether, forcing manufacturers to alter how they used particles within their offerings and the manner in which those offerings were marketed.

Today, particle balls are still a part of the bowling landscape, but it is rare to find them specifically marketed as such. Instead, manufacturers often play up the strength of the base resin and make non-specific references to the particle elements that are used to increase ball motion.

So, why did the addition of high particle loads boost the performance of certain bowling balls while noticeably diminishing that of others? The answer can be found in each ball's base resin formulation.

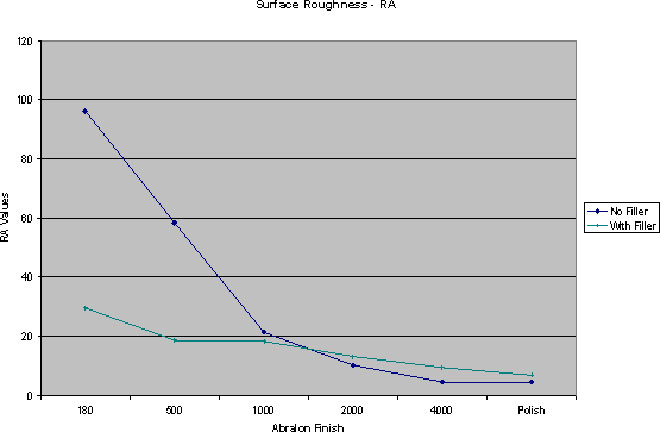

In the graphic 1 below, there are two lines of surface roughness data exhibited across several grit finishes of a particular coverstock formulation. The coverstock that has the line that slopes in a steeper fashion toward the lower grit ratings is the one that does not contain particles or fillers. The line that is straighter towards the lower grit ratings is the one with a particle load.

What can we tell from this data? We can tell that the base resin responds well to coverstock grit changes, but the added particles do not. Where the base resin can be manipulated to create noticeable differences in performance, the particle-infused resin offers very little room for manipulation or tailoring of performance. So, in this case, the non-particle ball will offer the bowler a great many more options than the particle ball. But this is not the case with all particles.

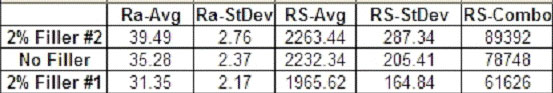

The second graphic below contains data concerning a base resin and two different particle fillers. As we can see, when two percent of filler number one is added to the base resin, the surface roughness of the coverstock decreases in comparison to that of the base coverstock. In contrast, when two percent of filler number two is added, the surface roughness increases by approximately 13-percent. Why did this happen? It is due to the chemical differences and sizes of the two particles. With everything else being held equal, filler number two will increase overall ball performance while filler number one will decrease overall ball performance.

The point of this analysis is to show that bowling ball performance is not dictated simply by whether a ball is reactive resin or particle. It is impacted by the formulation of the base resin and the size, load and chemical composition of the specific particles and fillers being used.

This analysis is necessary in order to fully comprehend the elements of bowling ball motion and the factors that add or detract from it. The USBC Equipment Specifications and Certification department seeks to make the elements of bowling ball motion understandable to bowlers of all ages and ability levels. For this reason, additional articles and examples will be published as the need arises. Readers are encouraged to examine the Bowling Ball Motion Study for more detailed information concerning this topic.

Reference

The article is courtesy of USBC