Difference between revisions of "PBA Plastic Ball Layout"

Mathistruth (talk | contribs) |

Mathistruth (talk | contribs) |

||

| Line 2: | Line 2: | ||

Un-drilled------ Low RG 2.685, int diff 0.000, total diff 0.026, diff ratio 0.00<br /><br /> | Un-drilled------ Low RG 2.685, int diff 0.000, total diff 0.026, diff ratio 0.00<br /><br /> | ||

| − | |||

3/4" Bal Hole--- Low RG 2.695, int diff 0.011, total diff 0.020, diff ratio 0.55<br /><br /> | 3/4" Bal Hole--- Low RG 2.695, int diff 0.011, total diff 0.020, diff ratio 0.55<br /><br /> | ||

| − | The final layout on this ball is 80* x 3.3" x 30*.<br /><br /> | + | The final drilled layout on this ball is 80* x 3.3" x 30*.<br /><br /> |

[[Image:Winning_layout_plastic_ball_nax4x45.jpg]] | [[Image:Winning_layout_plastic_ball_nax4x45.jpg]] | ||

Revision as of 05:40, 14 July 2010

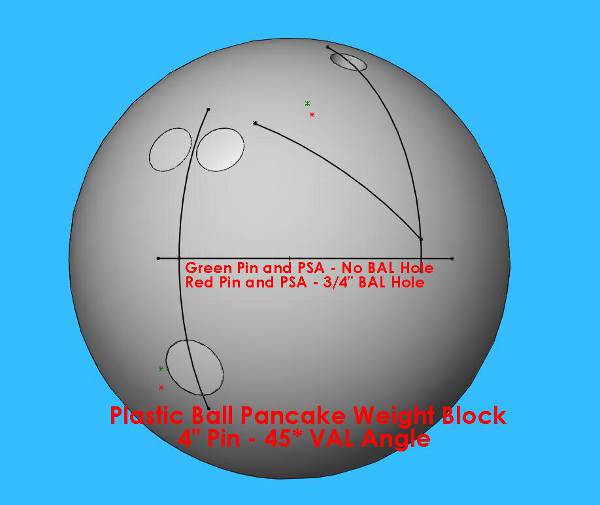

The PBA plastic ball layout began with a 4" pin and 45* VAL angle which can be seen in the following picture. The locations of the Pin and PSA before a balance hole and after a 3/4" balance hole can also be seen on the picture. The mass properties of the ball are:

Un-drilled------ Low RG 2.685, int diff 0.000, total diff 0.026, diff ratio 0.00

3/4" Bal Hole--- Low RG 2.695, int diff 0.011, total diff 0.020, diff ratio 0.55

The final drilled layout on this ball is 80* x 3.3" x 30*.

The following is copied from Mo's article in the June 2010 issue of Bowling This Month.

"For this layout, the cg / top of the pancake weight block is placed 4” from the bowler’s PAP at 45 degrees to the VAL, using “Dual Angle” terminology. The balance hole is placed at the intersection of a line drawn from the center of the bowler’s grip through the cg and the VAL. When using this technique, only make the balance hole big enough for the resulting static weights to be legal. The reason the cg / top of the weight block is placed 4”, not 3 3/8”, from the PAP is that the low RG axis of the ball moves to the right when holes are drilled into the ball.

The particular information for which we were looking was the intermediate (sometimes called the asymmetrical) differential and the total differential of the drilled ball. That layout produced an intermediate diff. of .011” and a total diff. of .020”. Let’s compare those numbers with the undrilled ball and a standard label drilled ball. The undrilled ball had no intermediate diff. and a total diff. of .026”. The standard label drilled ball had an intermediate diff. of .005” and a total diff. of .015”. In looking at those numbers, we were able to increase the total diff. of the drilled ball 33% with this layout when compared to the standard label drilling, but increased the intermediate diff. much more (120%) when compared to the standard label drilling. This is very significant since the increased intermediate diff. will result in the ball reading the pattern much harder and transitioning much faster. This should result in increased pin carry. AND IT DID! Since the winner, amateur Brian Zeisig, and the third place finisher, Walter Ray Williams, both used the layout. Many other bowlers also finished high in the standings using this layout.

An additional benefit is that this drilling increases performance of ALL pin in, low differential balls, such as entry level urethane and reactive resin balls. Some of the balls that this layout works well on are pin in (pins out less than 1”) versions of Brunswick’s New Slingshot, Brunswick’s Avalanche, Ebonite’s Tornado, the original Hammer designs, and all pin in balls with total diffs. of less than .039”." --- Mo Pinel